- 818-758-4076

- [email protected]

- 3146 Koontz Lane, California

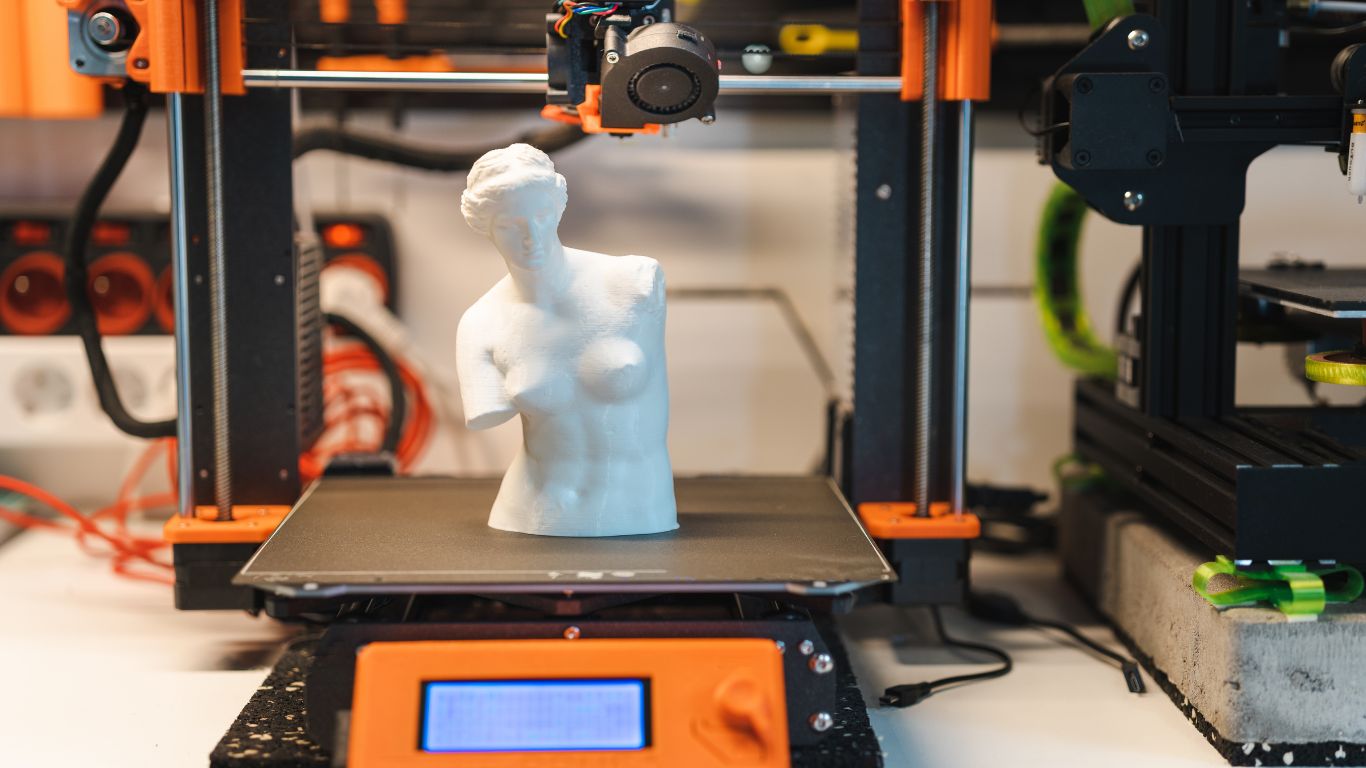

The Formlabs Form 2 utilizes SLA (Stereolithography) printing technology, enabling the production of incredibly fine, detailed objects, including moving parts like gears and hinges. It operates by filling the build chamber with liquid resin and using a UV laser to shape the object. If you need a prototype rapidly built, contact 3D Printing Dublin.

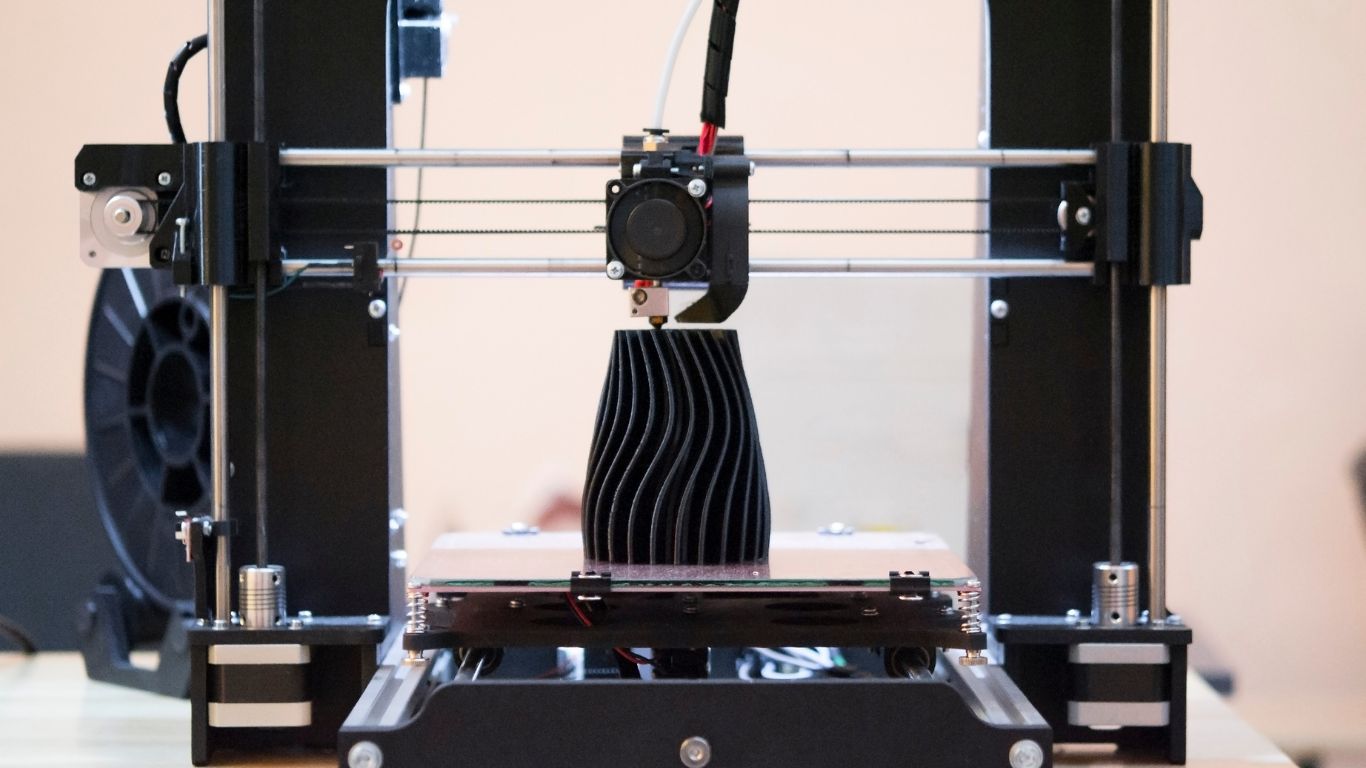

Our largest FDM (Fused Deposition Modeling) printer boasts a substantial build area of 300 x 300 x 400 mm (W x H x D), allowing for the creation of large prints using 1.75 mm PLA filament. FDM printing involves melting PLA or ABS plastic and layering it to build a solid object. While popular and affordable, FDM printing cannot produce moving parts. For such needs, refer to our SLA printer above.

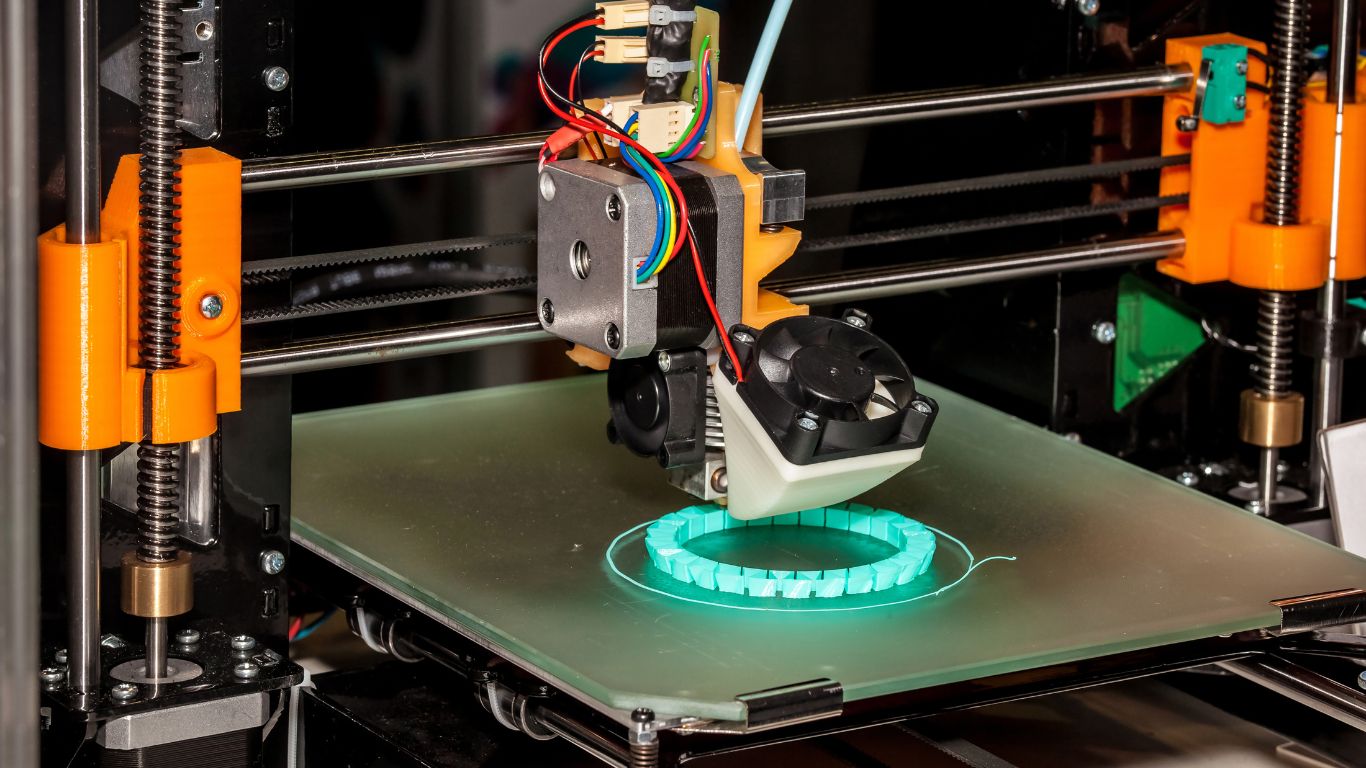

The Ultimaker 2 is renowned for its impressive print speed of up to 300 mm/s and a fine layer resolution of 0.02 mm. It offers a sizeable build area of 223 x 223 x 205 mm (W x H x D) and supports PLA and ABS plastics. This compact FDM printer operates quietly and uses 2.85 mm filaments. It features an easy-to-load filament system but requires manual calibration to within 1 mm before each print.

The UP Box is designed for large print jobs, offering a build volume of 255 x 205 x 205 mm (W x H x D). It features fully automated platform calibration, including automatic platform leveling and nozzle height detection via an integrated motorized probe. The enclosed build chamber ensures temperature stability and minimizes warping when printing large objects. This printer is ideal for hassle-free manufacturing.

FDM (Fused Deposition Modeling) printing involves melting plastic, which is then used to build a solid object layer by layer. Developed by Scott Crump over 20 years ago, this technology creates stable, durable models with high accuracy. It is environmentally stable and can produce complex figures and shapes that other manufacturing technologies cannot replicate. FDM printers are popular and widely used in smaller printers, making them the most affordable option for 3D printing.

However, FDM printing has some limitations. It cannot produce moving parts or high-end prototypes. Additionally, FDM printers require precise calibration and coding, which can be challenging for beginners. Unlike a typical office printer, FDM printers demand significant effort to operate correctly, reflecting their advanced capabilities.

In comparison, SLA (Stereolithography) printing is more complex than FDM printing. It involves directing a laser into a tank of liquid resin, fusing each layer to build a solid object. This process requires a full tank of resin, meaning you must have enough resin on hand for each print. Additionally, the resin and other materials used in SLA printing are significantly more expensive than those for FDM printing.

The advantages of SLA printing stand out when compared to FDM printers. SLA printers chemically bond the layers they create, resulting in much more solid and precise objects. Each layer is less than one hundred microns thin, which is exceptionally fine. The objects produced are also more durable and suitable for practical applications than those made with FDM printers. However, SLA printers use proprietary resins, requiring you to address any licensing issues before printing. Additionally, SLA printing is more challenging to learn than FDM printing.

Summarize your business so the visitor can learn about your offerings from any page on your website.

© All Rights Reserved.